What is a Power Brake Booster?

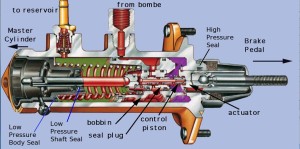

A power brake booster is a device that reduces the amount of force that it takes to apply hydraulic brakes. Most power brake boosters harness manifold vacuum to accomplish this, but some use hydraulic pressure or other methods. In a typical system that uses a vacuum brake booster, the brake pedal is attached to the booster via mechanical linkage, and the brake master cylinder is bolted directly to the other side of it. When the brake pedal is depressed, a vacuum-actuated server operates a plunger that activates the master cylinder.

Although vacuum brake boosters are almost ubiquitous, some vehicles use hydraulic brake boosters, which are powered by hydraulic pressure instead of vacuum. This pressure is provided by a drive belt-driven pump and may be tied into a hydraulic power steering system. In other cases, a vehicle may use a vacuum brake booster that uses a belt-driven vacuum pump instead of manifold vacuum.

Contents

History of the Power Brake Booster

Prior to the invention of the power brake booster, all brake systems were manual. That essentially means that in these manual braking systems, all of the braking power was generated by the force that the driver applied to the brake pedal. In practice, manual brake systems are difficult to operate due to the amount of force that it takes to depress the pedal, which was complicated by the fact that the average passenger car used to be a lot bigger and heavier than the average car that’s on the road today.

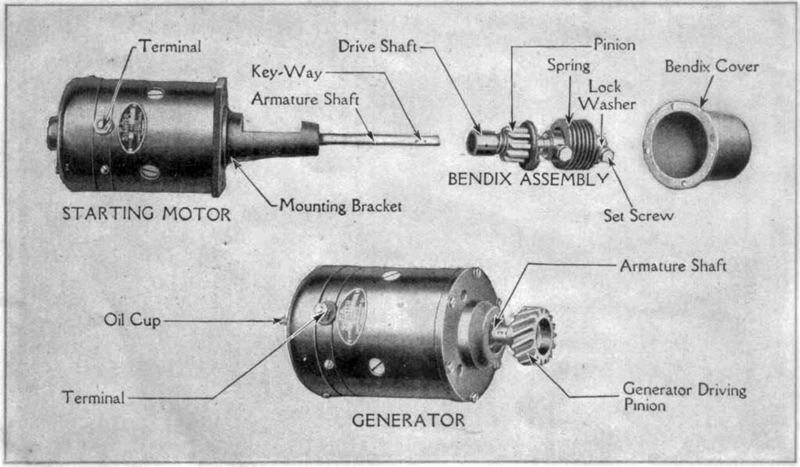

The first power brake booster was invented in 1927 by Belgian engineer Albert Dewandre. This system was similar to the vacuum brake boosters we use today, in that it utilized manifold vacuum to reduce the amount of force that it took to operate a brake pedal. This system was marketed by the Robert Bosch Company, and it first appeared on the Pierce-Arrow for the 1928 model year.

Although vacuum brake boosters were available from that point on, they didn’t become standard equipment until much later. Throughout much of the 20th century, vacuum brake boosters were offered as optional equipment alongside cheaper manual brake systems.

Hydraulic brake boosters appeared later, which various patents being granted throughout the latter half of the 20th century. Although hydraulic boosters failed to ever really catch on, they have been used in some vehicles where space was at a premium (i.e. the BMW E32), or manifold vacuum wasn’t available.

How Does a Vacuum Brake Booster Work?

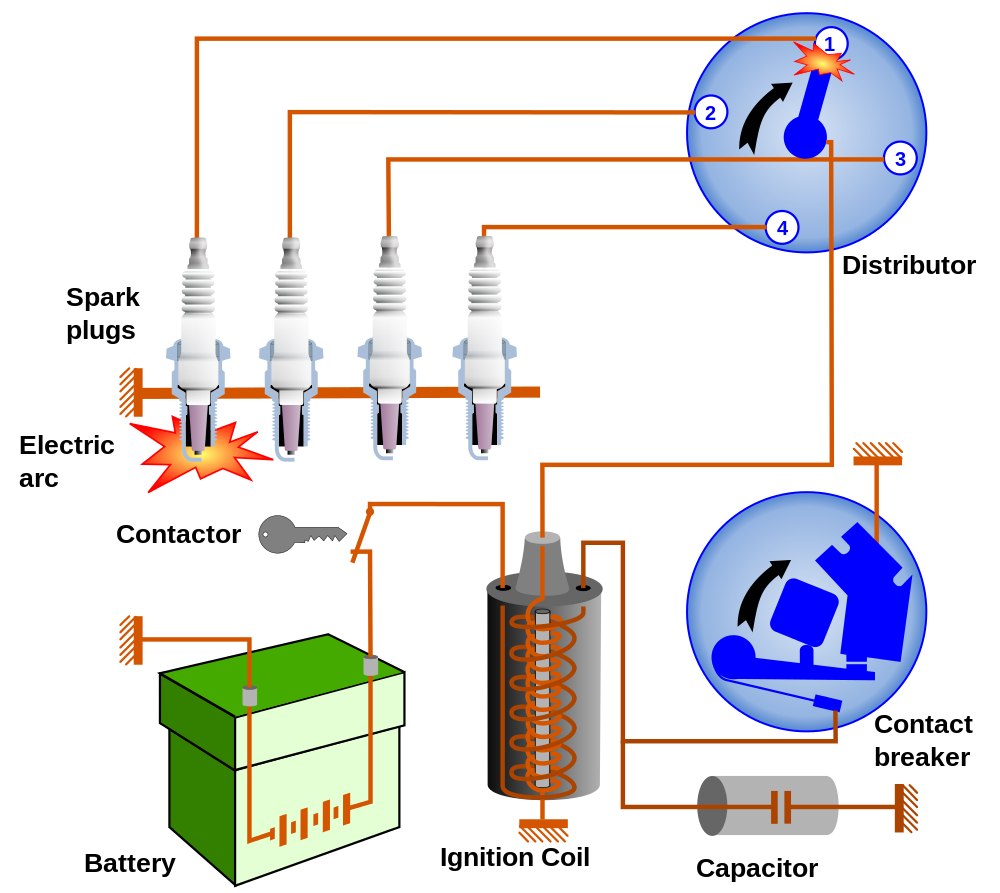

A typical vacuum brake booster consists of a large, hollow chamber that acts as a vacuum reservoir or tank. This casing is connected to manifold vacuum via a check valve and a vacuum hose. When the engine is turned on, an a partial vacuum is generated inside the intake manifold, all of the air is sucked out of the casing, which creates an internal vacuum. This vacuum is then used to provide assistance when braking.

When the driver presses on the brake pedal, it operates an input shaft on one side of the brake booster. This is connected to a vacuum-operated server, which itself is connected to the master cylinder push rod. If a vacuum exists inside the casing of the brake booster when the pedal is depressed, the servo will force its push rod into the brake master cylinder with relatively little effort.

What If There Isn’t Any Manifold Vacuum?

During normal operation of a naturally-aspirated gasoline-powered internal combustion engine, there will always be manifold vacuum whenever the brakes are required. Manifold vacuum is highest when the throttle plate in the throttle body or carburetor is closed, which means that the maximum level of vacuum is present whenever you aren’t pressing on the gas pedal. Although manifold vacuum drops significantly at wide open throttle, you shouldn’t normally have to hold a vehicle at wide open throttle while braking.

In vehicles that use turbocharged gasoline engines, and vehicles that use diesel engines, a lack of manifold vacuum is an issue. In these cases, there are a number of ways that vacuum can be provided to a power brake booster. In most cases, a belt-driven pump will provide a constant vacuum source whenever the engine is running.

In some cases, a vacuum canister or reservoir will also be used. This is essentially just a hollow vessel that has all of the air sucked out of it by a pump or natural manifold vacuum, which allows it to act as a backup when additional vacuum is required.

How Does a Hydraulic Brake Booster Work?

Hydraulic brake boosters use hydraulic pressure instead of vacuum to provide braking assistance. This pressure is usually generated by a belt-driven pump, and they are sometimes tied into another hydraulic system (i.e. the power steering.) This type of power brake booster is typically attached to the back of the master cylinder just like a vacuum booster, but it has two hydraulic lines instead of a single vacuum line. One hydraulic line is connected to the pump (the pressure side), and the other is connected to the hydraulic fluid reservoir (the return side.)

In much the same way that vacuum boosters work, hydraulic power brake boosters rely on a pressure differential to provide braking assistance. The main difference is that it is hydraulic pressure that does the work rather than a vacuum-actuated servo.

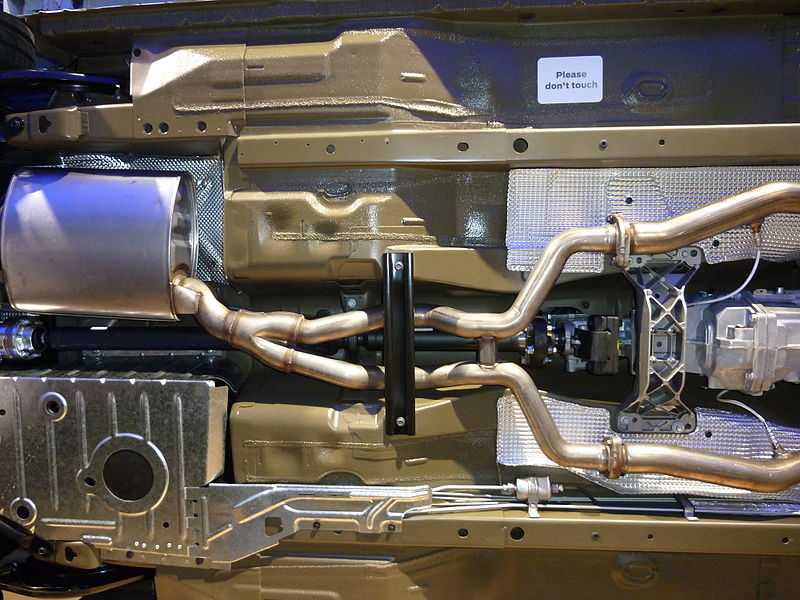

Since the hydraulic pressure is generated elsewhere, and often by a component that already performs another function, hydraulic brake boosters don’t take up as much space as vacuum brake boosters.

Power Brake Booster Failure

Although it’s possible to drive a vehicle that has a failed power brake booster, it isn’t especially safe. This is because it can be extremely difficult to brake effectively when a power brake booster fails. The pedal will be much stiffer than you are used to, which can make it impossible to apply as much force to the brake master cylinder as you would normally be able to.

If you notice an especially high, hard pedal when you are driving, your power brake booster may have failed. You may also be experiencing a severe vacuum leak at the booster or a loss of hydraulic power, both of which will also result in additional symptoms. In either case, you should make sure to account for the fact that you may experience radically increased stopping distances.

The fix for a failed vacuum brake booster is typically just to replace it, although they can sometimes be rebuilt. The issue may also be a vacuum leak or a bad check valve, which is a much easier fix.

Fine suitable information for seminar