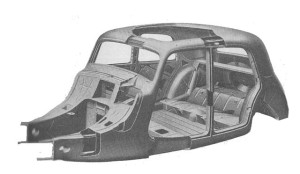

What is Monocoque Construction?

Monocoque construction is an automobile design technique that uses the exterior shell of the vehicle to provide structural support. This can be contrasted with traditional body-on-frame construction, which relies on the frame to provide structural integrity. Monocoque construction techniques were first used as early as 1912, but they didn’t catch on for a number of reasons. Today, a modified type of monococque construction called “unit body” or unibody is very popular.

Citroen was an early adopter of the modified-monocoque “unit body” construction technique in the 1930s.

The History of Monocoque Construction

In the very early days of the automotive industry, automobile designers leaned heavily on construction techniques that had been in use for centuries or longer. These early automobiles were built using body-on-frame construction, which was the exact technique that had been used to build horse-drawn carriages, and that technique proved to be very popular. In fact, it’s still in use today.

Monocoque construction originated in the aerospace field. Like automobiles, early airplanes utilized wood or metal frames that created the structural base for everything else to be built upon. However, this type of construction caused the weight of the frame to be a huge issue. That led to the development of monocoque construction techniques. One of the first aircraft to adopt these new construction techniques was built in 1912. This aircraft was the Deperdussin monocoque, and it had a body that was constructed from poplar veneer that were laminated and glued together. That effectively formed a structural shell that acted both as the aerodynamic, outer shell and the main load-bearing component, which greatly reduced the overall weight of the aircraft.

In 1922, the Lancia Lambda was the first production automobile to adopt monocoque construction techniques. In addition to the exterior body shell that provided a structural base for the vehicle, the Lamboda also attained additional structural support from its driveshaft tunnel.

Although Lancia introduced the first monococque automobile in the 1920s, and other automakers like Opel and Citroen experimented with their own designs in the 1930s, body-on-frame construction remained dominant for decades. It wasn’t until the 1960s that automakers started moving away from body-on-frame construction for smaller passenger vehicles, and even then the “unit body” style became prevalent rather than true monocoque designs.

Monocoque Vs. Unibody

There are two main types of automobile designs: structural shell and structural frame. Monocoque vehicles fall into the former category, while traditional body-on-frame construction makes up the second. Today, structural shell construction techniques have become dominant, especially for smaller vehicles, but very few vehicles are truly monocoque in nature.

The main difference between monocoque construction and unit body construction is that a monocoque vehicle consists of a single, structural component where the exterior skin of the vehicle provides the bulk of the structural integrity. In unit body construction, most of the structural integrity is provided by metal tubes, bulkheads, and box sections. There is no frame, but the stressed skin of the vehicle doesn’t provide any real structural support like in monocoque construction.

Great article, really illustrates the concept. I was trying to find out what monocoque meant in reference to a vehicle, as the new 2017 Q60 Infiniti coupe has this type of construction. I just took one for a demo… it was sweet. Great acceleration.