What is an Intake Manifold?

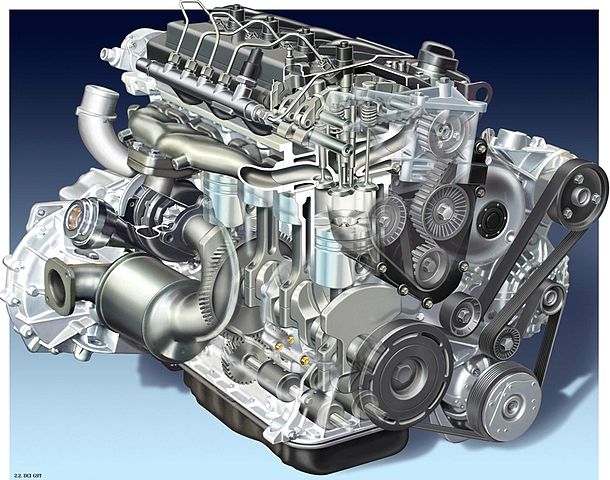

An intake manifold is a component that delivers either air or an air/fuel mixture to the cylinders. The design of these components varies widely from one application to another, but they all perform that same basic function, and they all have a single input and multiple outputs. In carbureted engines, the intake manifold connects the carburetor to the intake ports. In fuel-injected engines, the intake manifold connects the throttle body to the intake ports.

In addition to the basic functionality of connecting intake ports to the rest of the intake system, an intake manifold will often serve as the mounting point for other components. These manifolds sometimes also form an integral part of the cylinder head, in that they may serve to “seal” the top of an engine, particularly on internal combustion engines that have a V configuration. In addition to air (and fuel), intake manifolds sometimes also have coolant pass through them.

Contents

Intake Manifold Construction Materials and Designs

Most intake manifolds are cast from either aluminum or iron. Cast iron was the metal of choice throughout most of the 20th century, but aluminum has gained in popularity due primarily to the fact that it weighs a lot less. With that in mind, some intake manifolds are actually made out of lightweight composites to further reduce the weight of the components.

The most basic intake manifolds simply provide a path for air to pass between an inlet and multiple outlets.

Regardless of the construction material, intake manifolds are cast (or injection molded) components that consist of a single inlet and many outlets. This is actually the origin of the name as well, since the origin of “manifold” is the Old English “manigfeald” or “many folds.” In this sense, “many folds” indicates the way that an intake manifold “folds” together a series of inputs and outputs. On the other side of the internal combustion process, an exhaust manifold performs much the same function except in reverse (i.e. it “folds” multiple exhaust streams into one.)

The simplest intake manifolds bolt up to a cylinder head and provide an air-tight connection between the intake ports and the throttle body or carburetor. These manifolds are primarily found on “straight” engines (i.e. L4, L6) and flat engines (i.e. Subaru’s H4 and H6). In addition to the intake port and carb/throttle body connections, these simple intake manifolds typically have one or more vacuum ports and may serve as the mounting point for various other components.

More complicated intake manifolds are often found on V-type engines (i.e. V6, V8, etc). Due to the way that these engines are configured, the exhaust ports are typically located on the outside of the V shape, while the intake ports are located on the inside. These engines often have a “valley” that exposes components like lifters, push rods, etc. In addition to providing a connection between the intake ports and the carburetor or throttle body, intake manifolds for these engines also seal off the valley. Some of these intake manifolds also have coolant ports.

How does an Intake Manifold Work?

Intake manifolds work by evenly distributing either air or an air/fuel mixture from the carburetor or throttle body to the cylinders. This is accomplished through careful engineering of both the design and orientation of the manifold. If an intake manifold has too many abrupt changes in orientation or contour, the flow of air can be impeded, which would result in poor operation. With that in mind, aftermarket intake manifolds are often designed to be even more efficient than OEM components.

Intake Runners and Plenums

Although the simplest intake manifold design simply has to connect the intake ports to a common inlet, most manifold designs fare significantly more complex. A lot of modern intake manifolds use a system of runners that connect to a central “plenum” chamber. When properly engineered, this type of “resonance turing” design can increase volumetric efficiency above 100 percent through Helmholz resonance and the Venturi effect.

Manifold Vacuum

In addition to simply providing a path for air or air and fuel to move between a common intake and the intake ports, intake manifolds also perform another important function. Due to the way that internal combustion engines work, and the way that intake manifolds are “sealed” by the constant flow of air in one side and out the other, the movement of the pistons in the engine is able to effectively create a partial vacuum inside the intake manifold.

When each piston moves downward on the intake stroke, it sucks air (or air and fuel) out of the intake manifold. This creates a situation where the pressure inside the manifold is lower than the pressure outside of the manifold, which results in a partial vacuum. This vacuum is then harnessed to perform a variety of different functions that range all the way from climate controls to brake boosters.

Intake Manifold Failure

There are two primary sources of intake manifold failures: bad gaskets and cracked manifolds. Both of these issues result in additional air entering the intake system, which results in drivability issues. In systems that use a carburetor, a cracked intake manifold or a gasket leak will typically result in a poor or rough idle, while fuel-injected systems will typically have an extremely lean fuel mixture and a racing idle.

Since vacuum is used to power various other systems, leaks in vacuum lines or vacuum-powered components can result in the same symptoms that are created by a cracked manifold or bad gasket. That’s why it’s important to check out the vacuum lines and accessories instead of just focusing on the manifold itself and the gasket. And since some intake manifolds have coolant ports, it’s also possible for an internal or external coolant leak to develop due to manifold or gasket issues.

Manifold Vacuum as a Diagnostic Tool

Since manifold vacuum is produced by the normal operation of the engine, the level of vacuum can also be used to diagnose certain engine problems. For instance, low vacuum might indicate a burnt valve, incorrect valve or ignition timing, or a variety of other problems.