What is an Ignition System?

An ignition system is an array of components that are all involved in the process of igniting the air/fuel mixture in an internal combustion engine. Since there are two main types of internal combustion engines, there are also two main type of ignition systems and then a handful of other subtypes. Spark-ignited internal combustion engines can be broken down into magneto-type ignition systems and spark and coil systems, while diesel engines rely on compression to ignite the air/fuel mixture.

Contents

History of the Ignition System

Since ignition systems are made up of a number of different components, a lot of different moving parts had to come together before they could be developed. One of the earliest examples of some of the major principles utilized by spark-ignition systems dates back to 1780, when Alessandro Volta built a toy electric pistol that used an electric spark to ignite a mixture of hydrogen and air to shoot a cork.

Although Alessandro Volta demonstrated how an electric spark could be used to drive what essentially amounted to a piston, two major components had to be invented before the ignition system could be developed. The first component was the magneto, which is a device that uses magnets to generate an electric current. Faraday first demonstrated how a moving magnetic field could generate a current in 1831, but the first magneto ignition system didn’t appear until the 1890s.

Another watershed moment in the history of the ignition system was invention of the spark plug in 1860. This component, which is ubiquitous in modern spark-ignited internal combustion engines, was developed by Belgian engineer Etienne Lenoir for his gasoline engine.

At around the turn of the century, Rudolph Diesel developed the Diesel cycle. Unlike gasoline engines that use the Otto cycle, Diesel engines rely on compression instead of spark to ignite the air/fuel mixture. This resulted in the development of a completely different type of ignition system that sometimes utilizes components like glow plugs to assist in ignition.

In the early years of the 20th century, basic magneto ignition systems were developed into switchable systems. These systems were manually switchable from using replaceable dry cell batteries to start an engine and run it at low speeds to using magneto ignition at higher speeds.

The next major development in the history of the ignition system came in 1910, when Cadillac introduced an engine that utilized a battery and coil type ignition. This system had all of the same basic parts that were used for over half a century, including a battery-operated coil, a capacitor, points, and a distributor. Like modern ignition systems, the coil generated the current necessary to induce a spark, the points acted as the switch to trigger the coil, and the distributor sent the spark to the proper cylinder at the necessary time.

Modern ignition systems use electronic ignition instead of mechanical devices like points. The first electronic ignition system was developed by Delco-Remy in 1948, but they didn’t start to show up on cars and trucks for a while. One of the first instances of an electronic ignition system was offered by Pontiac in 1963, and the first solid state system also showed up that year.

Coil on plug ignition systems are a relatively recent development in the history of the ignition system.

The next major development was the introduction of electronically controlled ignition systems. These systems started to gain in popularity during the 1990s, and they are now used throughout the automotive industry. Instead of using a distributor to route current from a single coil, these systems use computer-controlled coil packs that are each connected to either one or two spark plugs.

Ignition System Components

Since there are a few different types of ignition systems, not every engine has the same ignition system components. The two main types of ignition systems are spark-ignition and compression ignition, and there are also a number of different types of spark-ignited systems.

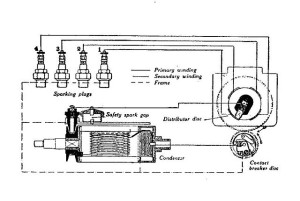

Magneto-type Ignition System Components

Magneto-type ignition system components typically include:

- a high tension magneto

- a condensor

- one or more contact breakers (sparking plugs)

- a distributor

In basic magneto-type ignition systems, the high tension magneto generates an electrical current that passes through a contact breaker (spark plug) in order to generate a spark and ignite the air/fuel mixture. These systems were popular in the early days of the automobile, but they are no longer used in automotive applications. Small engines, like those found in lawn mowers, often use these systems due to the fact that no battery is required for the ignition process.

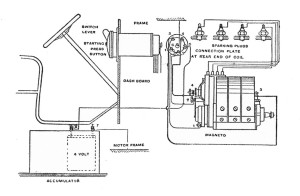

Switchable Ignition System Components

Switchable systems are hybrids, so they typically included:

- a magneto

- one or more dry cell batteries

- a coil

- a distributor

- two sets of spark plugs

One of the main drawbacks of magneto ignition systems is that the timing is fixed. In order to help deal with that situation, while not giving up the perceived reliability of the magneto, some vehicles were equipped with switchable systems. These ignition systems were hybrids of magneto and coil ignition, and they typically allowed the driver to switch over from coil to magneto after the vehicle was already started up and moving.

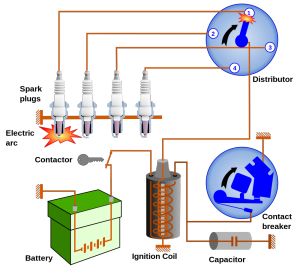

Battery and Coil Ignition System Components

Traditional battery and coil systems typically include:

- a coil

- points

- a condensor

- a distributor

- a distributor cap

- a rotor

- spark plug wires

- spark plugs

Battery and coil ignition systems really took off after the modern electrical system showed up, since the presence of a battery and a method of charging it (first the generator and later the alternator) made this a reliable method of ignition. These systems use battery voltage and a coil to generate the high current that’s necessary in order to jump the gap in a spark plug, and the ensuing spark is what ignites the air/fuel mixture.

Traditional battery and coil systems were entirely mechanical in nature, which means that they utilized points the activate the coil. These points are located inside of the distributor, and they have to be replaced on a regular basis as they wear out through normal use.

Electronic Ignition System Components

Electronic ignitions did away with mechanical components, so they include:

The major difference between electronic ignition and traditional battery and coil ignition is the lack of points. These systems are entirely solid state in nature, and they typically use an ignition module and some type of sensor or pickup inside the distributor to determine when the coil needs to be activated.

Modern electronically-controlled distributorless ignition systems are similar, but they omit the distributor altogether. Instead of a distributor, these systems have coils that are activated by computer controls. They also have more than one coil. Some of them have one coil per cylinder, and others have one coil for every two cylinders. In those cases, a “waste spark” system is used, which involves firing two spark plugs at a time, although only one is in a cylinder on its combustion stroke.

Diesel Ignition System Components

Diesel engines use compression ignition instead of spark ignition, so they are significantly different. These systems inject an air/fuel mixture into a cylinder, which is then compressed to the point where it gets so hot that it ignites without the need for a spark.

Although diesel ignition systems are relatively simple, they sometimes include components that make it easier to start when the engine is especially cold. One such component is the glowplug, which is essentially a small electric heater that is installed in either a pre-chamber or directly into the combustion chamber. Although glowplugs may look superficially like spark plugs, their only function is to provide enough heat for the compression ignition process to take place.

Some diesel engines also use intake manifold heaters or inject ether to help start the process of combustion.

Ignition System Failure

Since ignition systems consist of so many different parts, there are numerous different potential failure points. When a coil malfunctions, no spark will be present at the coil. When a distributor or rotor fails, there will be no spark present at one or more of the spark plug wires. The plug wires themselves can also fail, in which case they may short out to ground or break contact altogether.

In order to diagnose an ignition system failure, a methodical approach has to be taken in order to eliminate one potentially failed component after another until the culprit is ultimately located. This process typically consists of checking for spark at the plugs and then moving back through the system, and it will also include checking for power at the coil, testing the ignition module, and verifying the proper operation of other components.

When an ignition system failure leads to a misfire or other similar malfunctions, a scope is often used to determine which cylinders are misfiring and what the potential cause might be. Scope patterns can often be used to determine whether a plug is fouled, a plug wire is bad or shorted, or various other issues exist.