What is a Catalytic Converter?

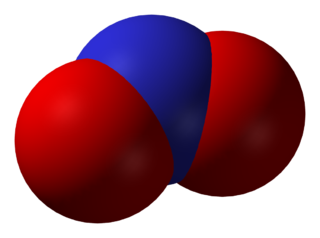

Catalytic converters are one of the major components found in modern exhaust systems. They are installed inline with the exhaust manifold, muffler, and connecting pipes, and perform an important function in relation to emission controls. These components function by catalyzing various chemical reactions in order to convert some of the more harmful or hazardous byproducts of internal combustion into more innocuous compounds. The three primary compounds that are dealt with by catalytic converters are CO (carbon monoxide), UHCs (unburned hydrocarbons), and NOx (nitrogen monoxide and nitrogen dioxide).

Contents

History of the Catalytic Converter

The history of catalytic converters can be traced back to the process of catalytic cracking, which is one of the conversion processes employed by petroleum refineries. This process, which transforms the heavier fractions of crude oil into gasoline, was developed by an American engineer of French extraction named Eugene Houdry. Whereas earlier attempts to turn substances like lignite and tars into gasoline suffered from problems with the catalyst, Houdry developed a way for the catalyst to be regenerated. The first of these catalytic cracking units was constructed in 1937, and Houdry’s technique was responsible for meeting the United State’s wartime aviation fuel needs after its entry into World War II.

After the war, Houdry became concerned with the growing levels of smog in and around Los Angeles, California. At the time, pollution from automobiles and industrial smoke stacks had led to the development of an immense amount of smog, and Houdry thought he could use his expertise in catalytic cracking to help solve the problem. This led to the founding of his Oxy-Catalyst company, and the development of early catalytic converters that were designed to be fitted on industrial smoke stacks.

After developing smoke stack “cats,” Houdry turned his efforts to creating a smaller, portable converter that could be installed on fork lifts and other machinery. This was effective, but there was one key difference between heavy equipment like fork lifts and automobiles: whereas the former used engines that ran on low-grade gasoline that contained no additives, automobile engines at the time ran on “leaded” gas that contained tetraethyllead.

Since the combustion byproducts of tetraethyllead in exhaust can effectively deactivate the catalyst in a catalytic converter by coating it, Houdry’s dream wouldn’t be realized for nearly two more decades. Additional work was done in the intervening years by engineers such as John Mooney and Carl Keith, and catalytic converters finally started to appear on production vehicles by the early 1970s.

Components of a Catalytic Converter

Although there are a few different types of catalytic converters, most of them contain three basic components:

- An outer body or container

- The core or substrate

- The washcoat

- The catalyst

The main exterior structure of a catalytic converter can vary in appearance depending on what type of converter it is. In any case, it is a component of the exhaust system that sits in-line somewhere between the exhaust manifold and the muffler. It may be bolted in place or held in place by u-clamps, and it may look like a slightly swollen pipe or have a substantially wider, flattened appearance.

Inside the exterior structure of a catalytic converter, you find the core or substrate. The most common substrate is a honeycomb-like monolith made out of a ceramic material. This type of substrate is most commonly found in production vehicles since it is relatively inexpensive to produce in quantity. If the monolith gets melted, or otherwise becomes plugged, it can result in severe driveability issues.

Some catalytic converters use a metallic core instead of a ceramic one. These cores are typically made out of a metallic foil composed of iron, chromium, and aluminum, and they are most often used in vehicles that don’t have large production runs due to cost issues.

In either case, a washcoat is used to coat as much of the surface area of the core with catalytic materials as possible. Various materials, including mixtures of alumina and silica, are used to create washcoats. Then, within the washcoat, the catalyst itself is suspended. These catalytic materials are typically precious metals like platinum, rhodium, and palladium, each of which performs a different function.

How Do Catalytic Converters Work?

Catalytic converters work primarily via catalytic chemical reactions. Since the converter is placed in-line between the exhaust manifold and the tail pipe, the entirety of the vehicles exhaust are forced to pass through it. When certain pollutant compounds pass through the monolith, they interact with the catalyst and are converted into less harmful substances.

The two main types of catalytic converters used in automotive applications are two-way and three-way. Two way converters are designed to oxidise carbon monoxide into carbon dioxide. This process involves adding an O2 molecule to each carbon monoxide molecule to create carbon dioxide:

2CO + O2 → 2CO2

At the same time, two-way converters also oxidize hydrocarbons into H2O and CO2. These hydrocarbons are present in the exhaust as either partially-burned or unburned fuel, so excessive hydrocarbons are typically the result of various problems that need to be repaired (i.e. a fuel mixture that is too rich.)

In the early 1980s, two-way converters were replaced by three-way converters in vehicles that use gasoline engines. In addition to oxidation reactions, these three-way converters also perform a reduction process that works on nitrates of oxygen. So, while these converters perform the same two functions that two-way converters do, they also reduce NOx to the component oxygen and nitrogen molecules:

2NOx → xO2 + N2

Catalytic Converter Theft

Catalytic converters are one of the primary components targeted by opportunistic thieves for a number of reasons. First of all, catalytic converters are external components that are relatively easy to remove. This is particularly true for vehicles that have a lot of ground clearance, where a thief can simply slide under the vehicle, unbolt the converter, and slide back out. Secondly, catalytic converters contain a number of precious metals that make them relatively valuable.

One solution to catalytic converter theft is to weld the converter in place, but this isn’t entirely effective. Although it prevents a would-be thief from simply unbolting the converter, it doesn’t stop him from cutting it off. Furthermore, if the thief cuts the pipes in front of and behind the converter, the repairs will be that much more expensive.