What is a Carburetor?

A carburetor is a device that mixes fuel and air together and delivers the mixture to the intake manifold of an internal combustion engine. Early carburetors achieved this by simply allowing air to pass over the surface of the fuel (i.e. gasoline), but most later dispensed a metered amount of fuel into the air stream.

Carburetion was the dominant method of mixing fuel and air for internal combustion engines until the 1980s, when emissions regulations and concerns about fuel efficiency resulted in fuel injection taking over. Although carbs were used in the United States, Europe, and other developed nations through the middle of the 1990s, they made use of increasingly complex control systems to meet emissions requirements.

Contents

History of the Carburetor

Different types of carburetors were developed by a number of automotive pioneers, including German engineer Karl Benz, Austrian inventor Siegfried Marcus, English polymath Frederick W. Lanchester, and others. Since so many different methods of mixing air and fuel were used in the early days of the automobile, and earlier, stationary gasoline engines also used carburetors, it’s somewhat difficult to pinpoint who “invented” the device.

These early carbs also differed in their basic method of operation from the “modern” carbs that were dominant throughout much of the 20th century. This is due to the fact that historic carb designs can be broken into two main types with an endless cavalcade of variations:

- surface carburetors

- spray carburators

Surface Carburetors

All early carburetor designs were “surface” carbs, although there was a lot of variety in this category. For instance, Siegfried Marcus debuted something called a “rotating brush carburetor” in 1888, and Frederick Lanchester unveiled his wick-type carburetor in 1897. The former used rotating brushes to expose gasoline to air from the intake, and the latter relied on one or more wicks to suck up gasoline.

The first carburetor to use a float was developed in 1885 by Wilhelm Maybach and Gottlieb Daimler, and Karl Benz also patented a float-style carb around the same time. However, these early designs were “surface carburetors” that relied on passing air over the surface of the fuel in order to mix the two.

Most surface carbs relied on simple evaporation, but others forced the issue. These were known as bubbling or filtering carburetors, and they operated by forcing up through the bottom of a volume of fuel. This resulted in a mixture of air and fuel above the main volume of fuel, which was then sucked into the intake.

Spray Carburetors

Although various surface carburetors were dominant during the very early days of the automobile, spray carbs started to take over right around the turn of the 20th century. Rather than relying on evaporation, these carburetors actually sprayed a metered amount of fuel into the air, where it was sucked into the intake. These carburetors used a float like Maybach and Benz’s earlier designs, but they operated based on the Bernoulli principle and also relied on the Venturi effect, just like modern designs.

One notable subtype of the “spray carburetor” is the so-called “pressure carburetor,” which first appeared in the 1940s. Although pressure carbs resemble spray carbs superficially, they were actually early examples of fuel injection. Rather than relying on the Venturi effect to suck fuel out of a bowl, pressure carbs sprayed pressurized fuel out of valves in a manner that was very similar to a modern fuel injector.

What Does Carburetor Mean?

Carburetor is an English word that is derived from the term “carbure,” which is French for “carbide.” In French, “carburer” simply means “(to) combine (something) with carbon.” Similarly, the English word “carburetor” technically means “(to) increase the carbon content (specifically of a fluid.)

Since air is a fluid, and gasoline is a hydrocarbon, a carburator is literally a device that adds gasoline (a hydrocarbon) to air (a fluid.)

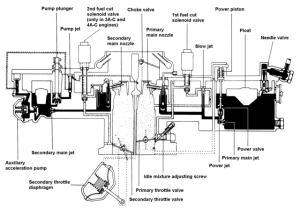

Components of a Carburetor

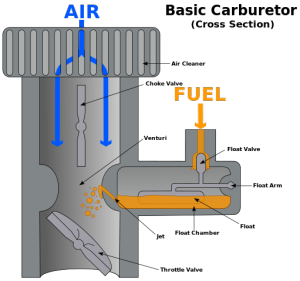

Different types of carburetors have different types of components, but modern spray type carbs all share a number of common characteristics, including:

- an air passage (venturi)

- a throttle valve

- throttle linkage

- a power valve or metering/step-up rod

- an accelerator pump

- a choke

- a bowl

- a float

- adjustment screws

- etc

How Does a Carburetor Work?

Different types of carburetors work via different mechanisms. For instance, wick-type carbs work by forcing air to pass over the surface of gas-soaked wicks, which causes gasoline to evaporate into the air. However, wick-type carburetors (and other types of surface carbs) were more or less obsolete more than a century ago. Most carburetors that are used by vehicles that are still in service today use a spray mechanism, and they all operate in more or less the same way.

Basic Principles of Carburetor Operation

Spray carbs work based on Bernoulli’s principle, which states that air pressure changes in a predictable way depending on how fast the air is moving. This is important because the air passage through a carburetor contains a narrow, constricted section called a venturi that causes air to speed up as it passes through. This is the section where the fuel inlets or “jets” are located, and the increased speed of the air causes fuel to be sucked into venturi.

The flow of air (rather than the flow of gas) through a carburetor is controlled by the accelerator pedal, which is linked to a throttle valve inside the carb. This valve closes off the venturi when the accelerator pedal isn’t in use, and it opens up when that pedal is depressed. That allows additional air to pass through the venturi, which sucks more fuel from the bowl, and subsequently provides more air and fuel to the engine for combustion.

Although that describes the basic operation of a spray carburetor, there’s a lot more going on in practice. Most carburetors include an additional valve above the venturi called a choke, which acts as a secondary throttle valve. The choke remains partially closed when an engine is cold, which reduces the amount of air that can pass into the carb. That results in a richer air/fuel mixture, so the choke has to open (either automatically or manually) once the engine has warmed up and no longer needs a rich mixture.

Other carburetor components are also designed to affect the air/fuel mixture during different types of operating conditions. For instance, a power valve or metering rod can increase the amount of fuel under open throttle, either by responding to low manifold vacuum or the physical position of the throttle valve.

Carburetor Failure

Some carb problems can be solved by adjusting the choke, mixture, or idle, and others require a rebuild.

When a carburetor fails, the engine will run poorly in certain conditions. Some carburetor problems result in an engine that is unable to run at idle without assistance, and others result in various rough running conditions. The most common issues are tied into cold engine conditions, and a carburetor that works poorly when an engine is cold may work just fine when it is warm due to problems with the coke or other components.

In some cases, carburetor problems can be solved by manually adjusting the mixture or idle speed. To that end, the mixture (which may be either too lean or too rich) can typically be adjusted by turning one or more screws that are attached to needle valves. These screws physically change the position of the needle valves, which allows the amount of fuel to be reduced (resulting in a leaner mixture) or increased (resulting in a richer mixture) depending on the situation.

Carburetor Rebuilding

Many carburetor problems can be solved by making adjustments or performing other fixes while the carb is still on the car, but other issues can only be dealt with by removing the unit and rebuilding it. A carburetor rebuild operation typically involves removing the unit, taking it apart, and cleaning it with a solvent that is designed specifically for that purpose. A number of internal components, seals, and other parts are then replaced before the unit is reassembled and installed.